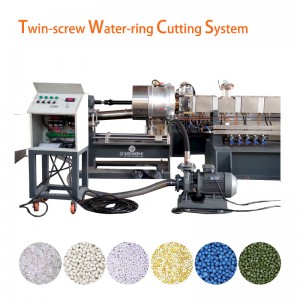

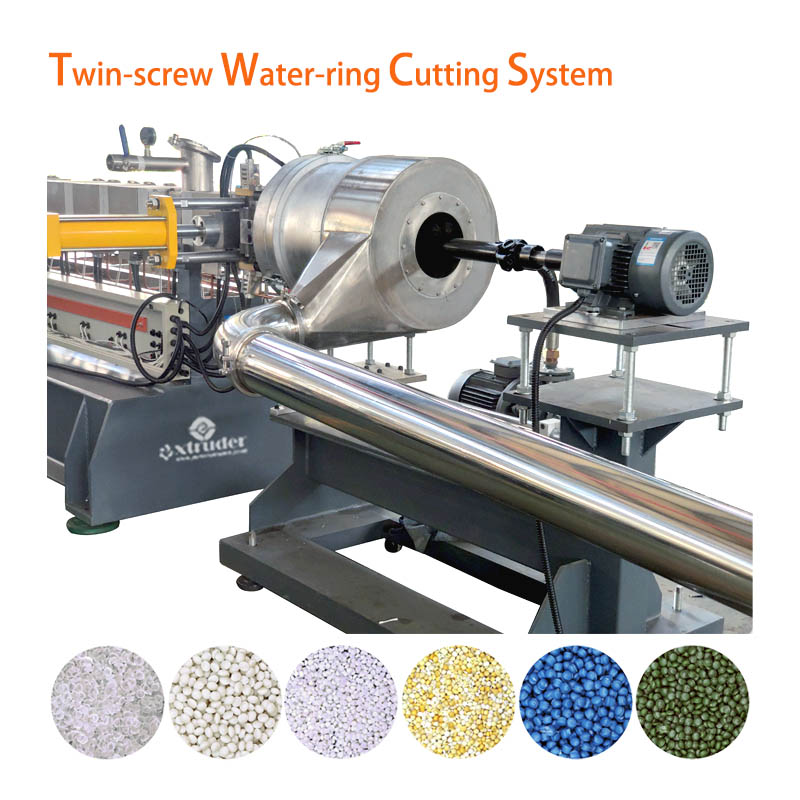

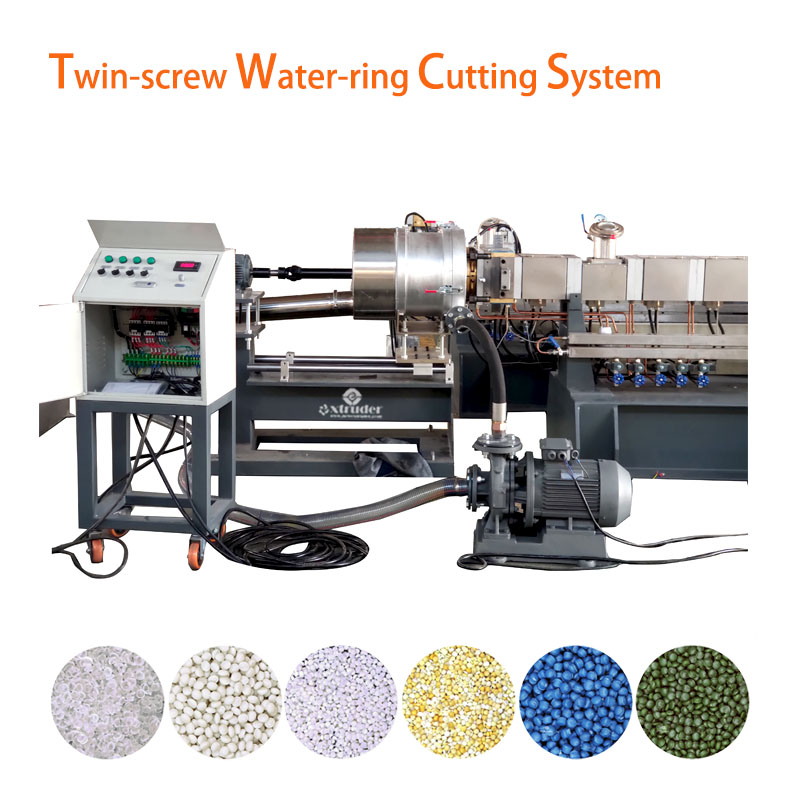

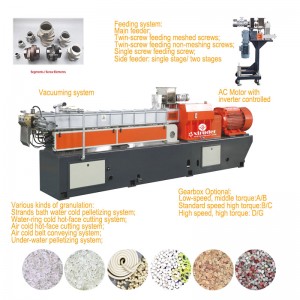

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

This kind of twin screw extruder can make good shape particles to match picky customers' requests.

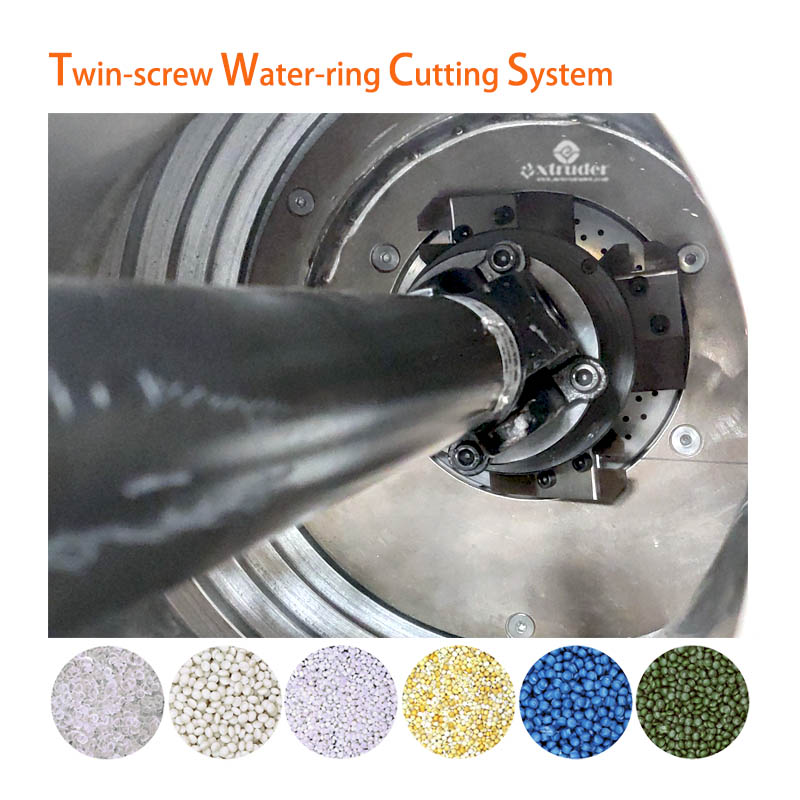

Q: What is the difference between extruder water ring cutting and underwater cutting(Pelletizing)?

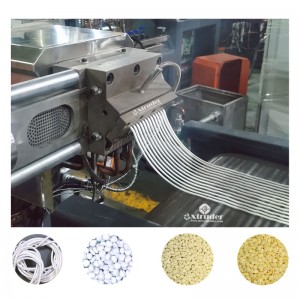

A: *. Water ring granulation is made by throwing the plastic into the water circulation

cylinder by its centrifugal action after the film surface granulation.

*. Underwater grilling means that the grilling of plastic steel at the die surface

does not have to be thrown out by centrifugal action, but must be driven by

water pressure through the die surface towards hydrolysis.

The Detailed Technical Parameter is as follows:

Model: SHJ-65B

L/D ratio:48:1

Motor powder:90KW-6P

Screw-speed : 500rpm

With a horizontal type mixing hopper made of stainless steel;

Far infrared heaters were equipped;

water-ring cooled hot-face pelletizing system

with dewater and vibrating sieve;

Q & A / Questions & Answers

Answer: The twin-screw Extruder also has great Advantages in plastic modification, because the screw element is a building block design, according to the different materials and its own characteristics, the free combination of the screw element and meet the customer’s requirements for finished particles.

At the same time because there are two screw rotation itself will produce friction heat, in the temperature will have an increase and then have a certain impact on the material, will further have the function of melting, mixing, so he will have more advantages in this respect than a single screw.

Answer: First of all, you have to determine which kind of raw material is your own, such as PE, PP, PVC, or other types of plastic, such as ABS, PC, PS, etc., with different material melting temperatures and degradation temperature is not the same. After the material is determined, the length-to-diameter ratio can be selected to determine the length of the machine, and then the appropriate models can be selected according to the customer’s demand for capacities, such as 20 machines for experimental models, 35 machines for experimental and small batch production, or large production models, such as 50, 52, 58, 60, 65, 75, 95. 135 model, etc.

A: Twin-screw extruder has absolute advantages over the single screw in modification, so in general, it is the first choice of customers in the field of modified plastic application. For example, in the material filled with calcium carbonate, barium sulfate, sodium sulfate, talc, titanium dioxide, and other filler production; Color MASTER PRODUCTION, ENGINEERING MATERIAL, AND SPECIAL FUNCTIONAL MASTER PRODUCTION, such as ANTI-STATIC, anti-aging, ANTI-ULTRAVIOLET (or ultraviolet absorption) and so on. In short, to add a variety of additives in raw materials or fill low-cost raw materials to reduce the cost of particles to the specified requirements, it is necessary to choose to use a twin screw extruder (granulator or sheet machine).

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |