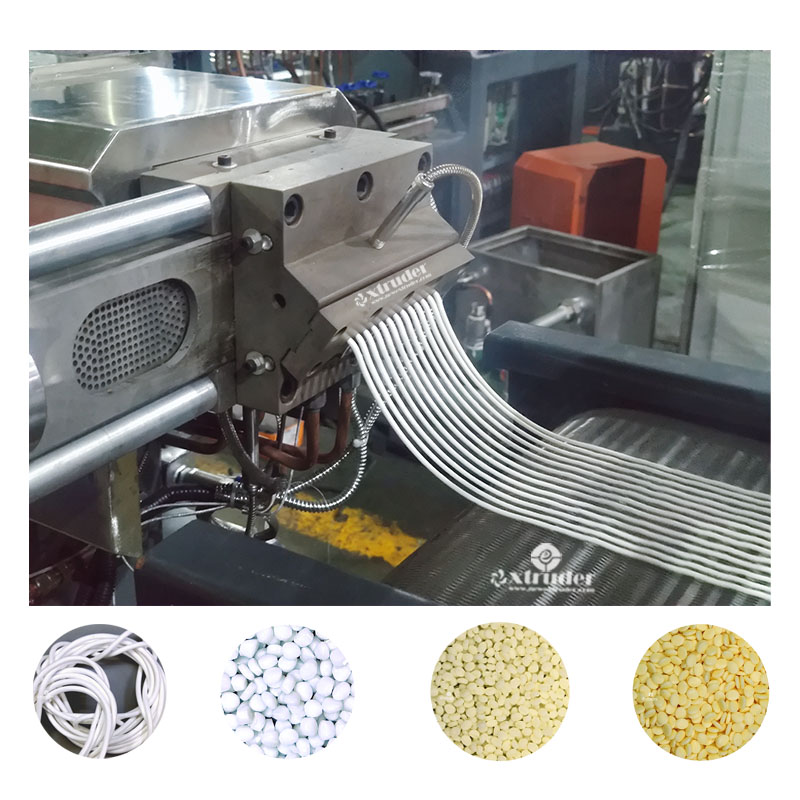

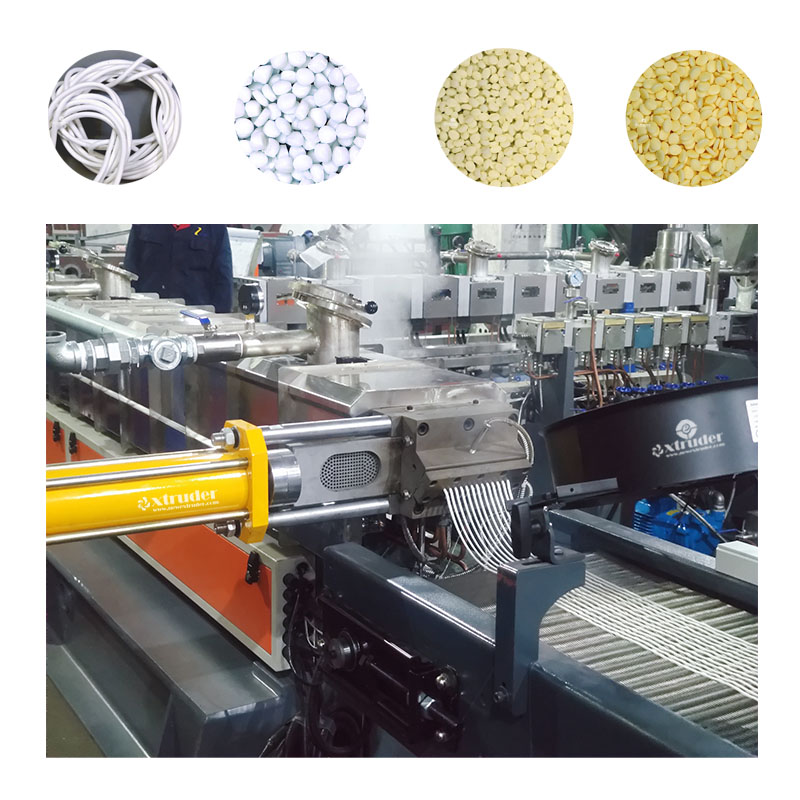

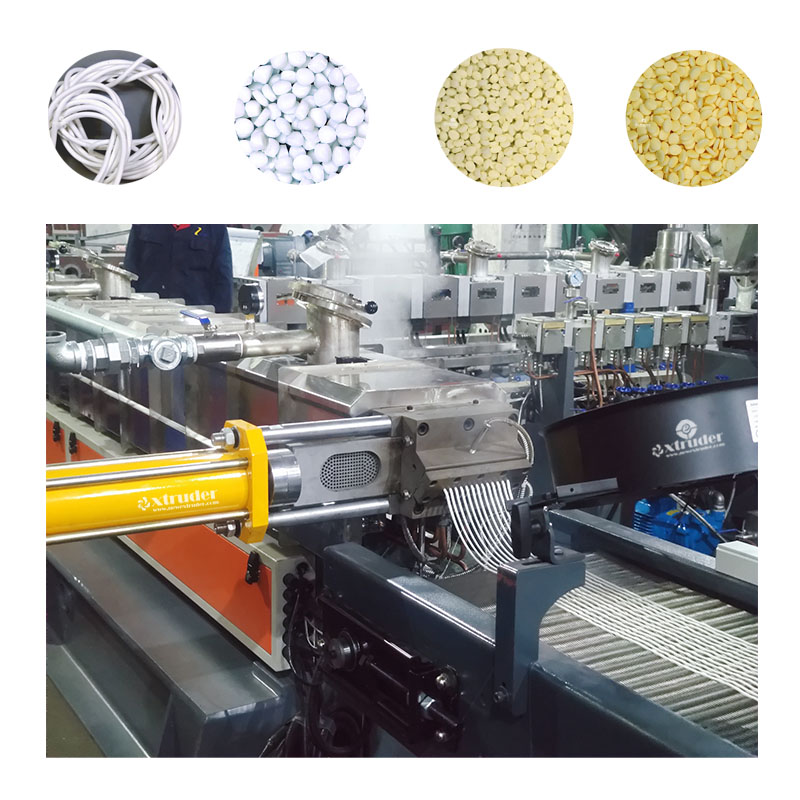

BIO-Degradable PBAT PLA Starch mixed particle extruder

This Twin-screw plastic extruder is for BIO mass and degradable plastic particle-making like to say PBAT,+PLA +St. (Corn starch, tapioca,cassawa starch)or CaCO3 powder added for granule making if need to make degradable sheets, please see our sheets-making lines.

HS CODE: 8477.2010

PBT resin is a crystalline, linear saturated polyester, which is one of the engineering plastics with excellent comprehensive properties. In the five engineering plastics, PBT is the latest industrialization and the fastest development of a variety. It is mainly used in automobile manufacturing, electronic appliances, optical fiber communication, but also can be used in the textile industry. PBT can maintain good mechanical properties in a wide temperature range, and excellent heat and chemical resistance, electrical properties. In addition to the traditional application in elastic jeans, bathrobes, sportswear and other aspects, it can also be used to make special clothing materials or high-elastic yarn for clothing.

We set such twin-screw plastic modification machine lines for XINJIANG Blue Ridge Tunhe Sci. & Tech. Co., Ltd.

(One of the Biggest manufacturers in Asia for PBAT, PBT, and PBS degradable plastic resin granule making.)

for PBAT, PBS with Starch and Calcium carbonate powder modification.

The use of degradable plastics is mainly in two areas: one is the original use of ordinary plastic areas. In these areas, plastic products used or consumed are difficult to collect back to cause harm to the environment, such as agricultural mulch and disposable plastic packaging, and plastic is used to replace other materials in the field. The use of degradable plastics in these areas can bring conveniences, such as golf tees for the golf course, and nursery stock for tropical forest planting. Specific application in:

1, agriculture, forestry and fisheries, plastic film, water retention materials, seedling bowls, seedbeds, rope nets, pesticides, and agricultural fertilizer slow-release materials.

2, packaging industry, shopping bags, garbage bags, compost bags, disposable meal boxes, convenient noodle bowls, and buffer packaging materials.

3. Sporting goods, golf tee, and tees

4. Sanitary products, women’s sanitary products, baby diapers, medical mattresses, disposable razor.

5, medical materials, bandages, clips, cotton swab sticks, gloves, drug release materials, as well as surgical sutures and fracture fixation materials.

The Duo-Vacuum system for Bio-degradable extruder, and the Twin screw extruder could be set a side feeder for extra additional raw material.

The use of degradable plastics is mainly in two areas: one is the original use of ordinary plastic areas. In these areas, plastic products used or consumed are difficult to collect back to cause harm to the environment, such as agricultural mulch and disposable plastic packaging, and plastic is used to replace other materials in the field. The use of degradable plastics in these areas can bring conveniences, such as golf tees for the golf course, and nursery stock for tropical forest planting. Specific application in:

1, agriculture, forestry and fisheries, plastic film, water retention materials, seedling bowls, seedbeds, rope nets, pesticides, and agricultural fertilizer slow-release materials.

2, packaging industry, shopping bags, garbage bags, compost bags, disposable meal boxes, convenient noodle bowls, and buffer packaging materials.

3. Sporting goods, golf tee, and tees

4. Sanitary products, women's sanitary products, baby diapers, medical mattresses, disposable razor.

5, medical materials, bandages, clips, cotton swab sticks, gloves, drug release materials, as well as surgical sutures and fracture fixation materials.

Technical rough parameter:

Screw Speed : 400rpm L/D ratio: 52:1 Main motor: 160KW controlled by inverter;

Horizental type with mixing blade hopper feeding system for barrels Extra size & new designed feeding barrel for the extruder Far IR Heaters for barrels

Gantry type pelletizer equipped material buffer collector The Silo with material vacuum extractor (Power: 5.5KW)

|||About Degradable Plastic Products & desposable plastic products:

What is degradable plastic and what is the main product after degradation?

Degradable plastics refer to environmentally harmless substances such as carbon dioxide, methane, water, and mineralized inorganic salts that are completely degraded under certain circumstances or in natural environments. As a new kind of polymer material, degradable plastics include many types, and the technical route is also developing constantly.

From the perspective of raw materials, biodegradable plastics can come from both petrochemical raw materials and biomass materials.

From the degradation mechanism, degradable plastics include biodegradation, photodegradation, oxidation degradation, and so on

From the degradation effect, it can be divided into “total” degradation and “partial” degradation.

The main function of degradable plastics is to reduce the non-degradable plastic products use by the environment brought by the non-degradable “white pollution”, but also to give the environment a better chance of sustainable development, improve the quality of the environment and reduce the pressure of environmental development, for the benefit of human development.

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |