Color Masterbatch filler masterbatch Recycling granulation TwinScrew Plastic Extruder has side-feeder SHJ65 Series

Color Masterbatch filler masterbatch Recycling granulation TwinScrew Plastic Extruder has side-feeder SHJ65 Series

Model: SHJ65A, SHJ65B, SHJ65C, SHJ65D,SHJ65G

HS CODE: 8477.2010.00

This machine line is wild used for many business field, like filler, master batch, engineering granules, bio mass, bio-degradable extrusion, GFL ( glass Fibre added) and other modification plastic business scope.

HS CODE: 8477.2010.00

This machine line is wild used for many business field, like to say, filler, master batch, engineering granules, bio mass, bio-degradable extrusion, GFL ( glass Fibre added) and other modification plastic business scope.

This machine line has different kind of cutting system:

1) air cooling hot-face cutting system;

2) air cooling belt convoying system;

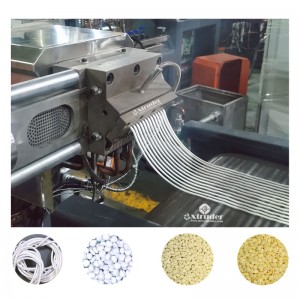

3) strand bathing water cooled pelletizing system;

4) water-ring cooled hot-face cutting system;

5) under water cutting system;

Co-rotating Parallel Twin Screw Plastic Polymer Extruder

Rough configuration for strand bathing water cooled system:

Model: SHJ-65 (A/B/C/D/G)

Output capacity: the output capacity is around 180-400Kgs/h,

L/D ratio:40:1 (STANDARD)<36-60 is possible for special request>

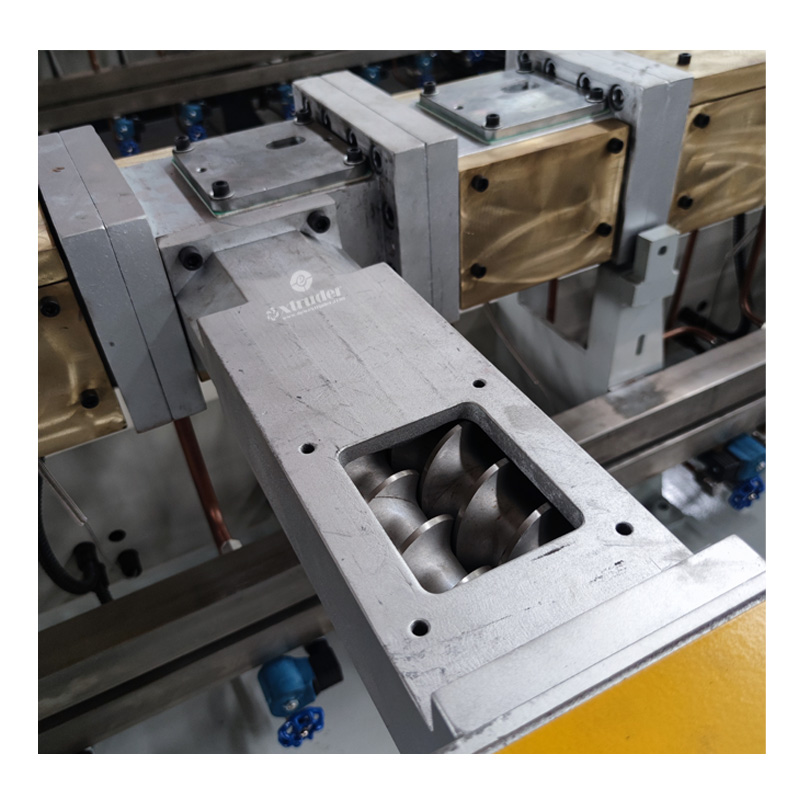

Screw Dia.: 62.4mm

Barrel hole Dia.: 63mm

Whole hardness: 62-64

Screw Speed: 400/500/600 rpm

Motor power: 75Kw/90Kw/110Kw, Wannan or Siemens-beide brand;

Machine line includs HOST, Power cabinet, water trough, air knife, pelletizer and some spare parts.

This SHJ-65 Twin Screw Plastic Polymer Extruder is for wild usage, not only for engineer granules making, but also for single color(white, black, red or other single color large output capacity orders.) master batch, functional granules(anti-static, anti-flame, fire retared, anti-UV,anti-aging granules.) production. If you need to produce the sheet or panel, then just change the die-head when you place the order to us or equipped extra die-head and other auxiliary equipments ( Auxiliary machine, like three rollers calander, dragging machine and others.)

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |