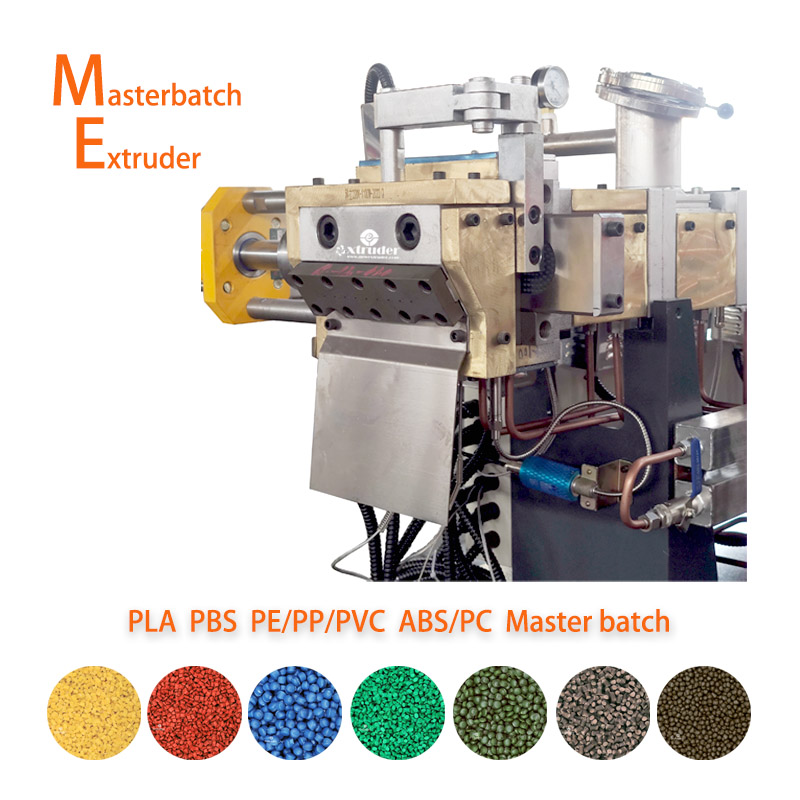

Color masterbatch PET color masterbatch Plastic Extruder Machine

PET: polyethylene terephthalate

polyethylene terephthalate Chemical formula is -OCH2-CH2OCOC6H4CO-

English name: PET Terephthalate,

short abbreviate is: PET, it’s a thermoplastic resin

HS Code: 8477.2010

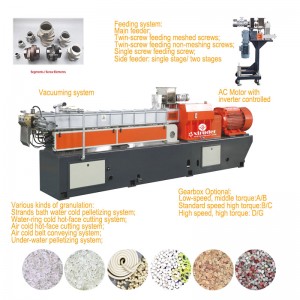

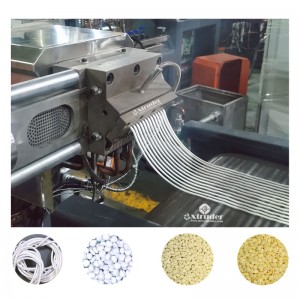

Screw speed: 400rpm, 500rpm for optional;

L/D ratio: 44:1

Motor power: 55KW

Heater: casting copper

Screen change with hydraulic workstation

Cooler: SL526

PET is a milky white or light yellow highly crystalline polymer with a smooth, glossy surface. Good creep resistance, fatigue resistance, friction resistance and dimensional stability, small wear, and high hardness, with the greatest toughness of thermoplastics: good electrical insulation performance, little affected by temperature, but poor corona resistance. Non-toxic, weather resistant, good stability against chemicals, low water absorption, resistance to weak acids and organic solvents, but not heat resistant to water immersion, not alkali resistance.

PET resin has a high glass transition temperature, slow crystallization rate, long molding cycle, long molding cycle, large molding shrinkage, poor dimensional stability, brittle crystallization molding, and low heat resistance.

In addition to the properties of PBT, PET has the following characteristics nucleating agents as well as improvements in crystallizing agents and glass fiber reinforcement.

1. Thermal deformation temperature and long-term service temperature are the highest in thermoplastic general engineering plastics.

2. Because of its high heat resistance, the enhanced PET is impregnated for 10S in the solder bath at 250℃, with almost no deformation and no discoloration. It is especially suitable for the preparation of electronic and electrical parts for solder welding:

3. The bending strength is 200MPa, the elastic modulus is 4000MPa, the creep resistance and fatigue property are good, the surface hardness is high, and the mechanical property is similar to that of thermosetting plastics.

4. PET resin and reinforced PET are the lowest-cost engineering plastics and have a high-cost performance because the price of ethylene glycol used in PET production is almost half that of butanediol used in PBT production.

PET is mainly used for fibers, with a small amount used for films and engineering plastics. PET fibers are mainly used in the textile industry. PET film is mainly used in electrical insulation materials, such as capacitors, cable insulation, printed circuit wiring substrate, electrode groove insulation, etc. Another application area for PET films is wafer base and baseband, such as motion picture film, X-ray film, audio tape, electronic computer tape, etc. PET film is also used to vacuum transfer aluminum into metalized film, such as gold and silver wire, micro capacitor film, etc. Another use for PET is in blow molding products, and polyester stretch bottles for packaging.

Glass fiber reinforced PET is suitable for electronic and electrical and automotive industries, used in various coil skeletons, transformers, TV, recorder parts and shell, automobile lamp holder, lamp shade, white heat lamp holders, relays, sun rectifiers, etc.

Address

8787 Winchester Blvd.

Campbell, CA 95008

sales@loremipsum.com

support@loremipsum.com

Sales: 1-800-694-7466

Support: 1-800-800-2775

Phone

Hours

Monday-Friday: 9am to 6pm

Saturday, Sunday: Closed

WANT TO WORK WITH US?

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |